|

Allied Foam Tech Corporation (since 1994) FOR OVER 20 YEARS ALLIED HAS BEEN PROVIDING TO CLIENTS WITH THE HIGHEST PERFORMING AQUEOUS FOAM SOLUTIONS & TECHNOLOGIES IN THE INDUSTRY |

| 2024 |

| Allied Developed the Best Fire Rated Composites per ASTM-E119 Test (www.firebarrierfoam.com) |

|

Allied fire barrier panels, boards have the highest compressive and

bending strengths vs autoclaved & cast-in-place foam cement products |

| Cement Composite | Cure Condition | Density | Compr. Strength | Bending Strength |

| AFT Fire Barrier Foam I | RT | 35 pcf | 900 - 1,000 psi | 370 - 500 psi |

| AFT Fire Barrier Foam II | RT | 35 pcf | 650 - 750 psi | 300-350 psi |

| AFT Portland Cem I/II | RT | 35 pcf | 400 - 450 psi | 100-200 psi |

| Autoclaved Concrete | Autoclaving | 35 pcf | 600 - 700 psi | 100 psi(?) |

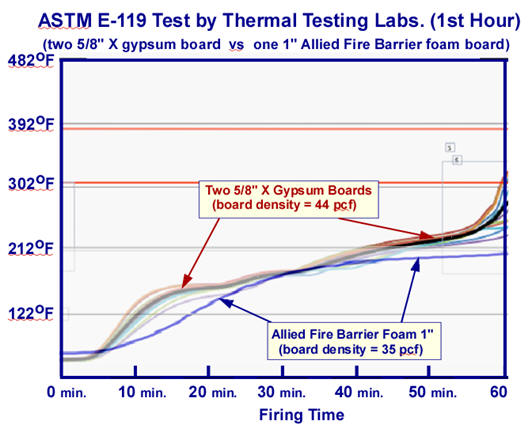

| Allied fire barrier foam has the highest fire rating per ASTM-E-119 Test against fire rated X-gypsum boards |

|

|

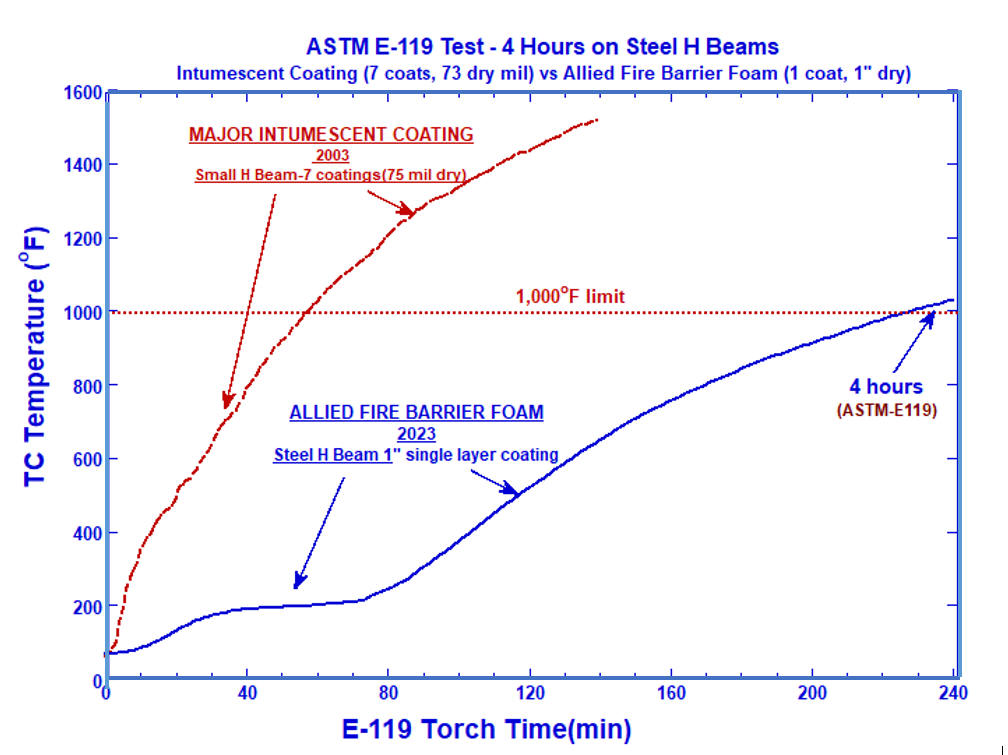

Allied fire barrier foam has twice or better fire ratings per

ASTM-E-119 Test over all fire rated intumescent coatings |

|

| ASTM-E-119 Tested H-Beams with Fire Rated Coatings |

|

|

| H

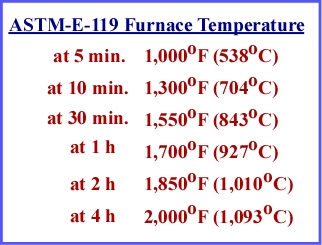

Beam with Allied Fire Barrier Foam - 4 Hours to 2,000oF |

H Beam with Intumescent Coating

- 2 Hours to 1,850o F |

|

|

|