|

ALLIED FOAM TECH

CORP. (SINCE 1994) (Please visit our fire barrier foam site with more focus on our fire rated composites development - www.firebarrierfoam.com) |

| 2024 |

| How Fire Barrier Foam Cement Enhances Fire Resistance in Structures |

| Allied Developed the Best Fire Rated Foam Composites per ASTM-E119 Test |

| (highest fire barrier rating, vermiculite-free & non-hazardous) |

|

|

|

MISSION STATEMENT |

|

Performance of currently available fire rated building materials,

tested under commonly used thicknesses and densities, are

really limited or inadequate in an actual fire. |

|

Allied powerful fire barrier foam technologies/composites could really have a chance to significantly

reduce financial losses, save lives and save the environment

during an actual fire.* |

| * confirmed recently by a major thermal testing lab. on A36 steel H beam per ASTM-E-119 test |

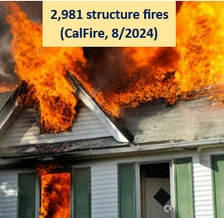

| FIRE HAZARD & TOXIC FUME RELEASE OF FLAMMABLE EXTERIOR BLDG. COMPOSITES |

| (effective fire barrier composites could avoid or significantly reduce the fire advancement) |

| (17,000 Californians to be striped of Fire Insurance (8, 2024) |

|

|

|

|

|

| California, 8, 2024 | Colorado, 12, 2021 | Tianjin, 8, 2023 | Dubai, 11,2022 | London, 6, 2017 |

|

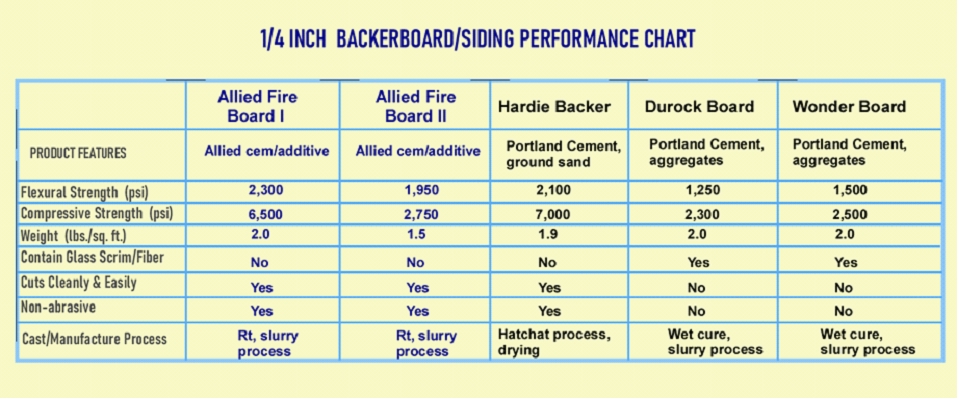

Allied fire barrier panels, boards have the highest compressive and

bending strengths vs autoclaved & cast-in-place foam cement products |

| Cement Composite | Cure Condition | Density | Compr. Strength | Bending Strength |

| AFT Fire Barrier Foam I | RT | 35 pcf | 900 - 1,000 psi | 370 - 500 psi |

| AFT Fire Barrier Foam II | RT | 35 pcf | 650 - 750 psi | 300-350 psi |

| AFT Portland Cem I/II | RT | 35 pcf | 400 - 450 psi | 100-200 psi |

| Autoclaved Concrete | Autoclaving | 35 pcf | 600 - 700 psi | 100 psi(?) |

|

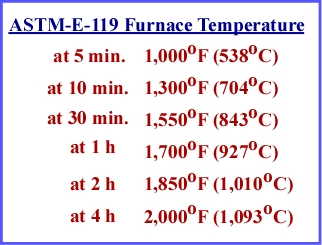

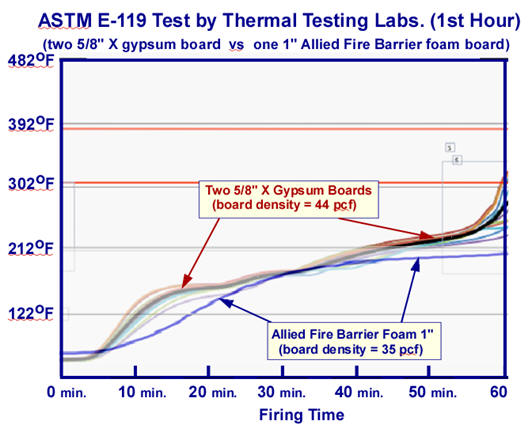

Allied fire barrier foam has the highest fire rating per

ASTM-E-119 Test against fire rated X-gypsum boards |

|

|

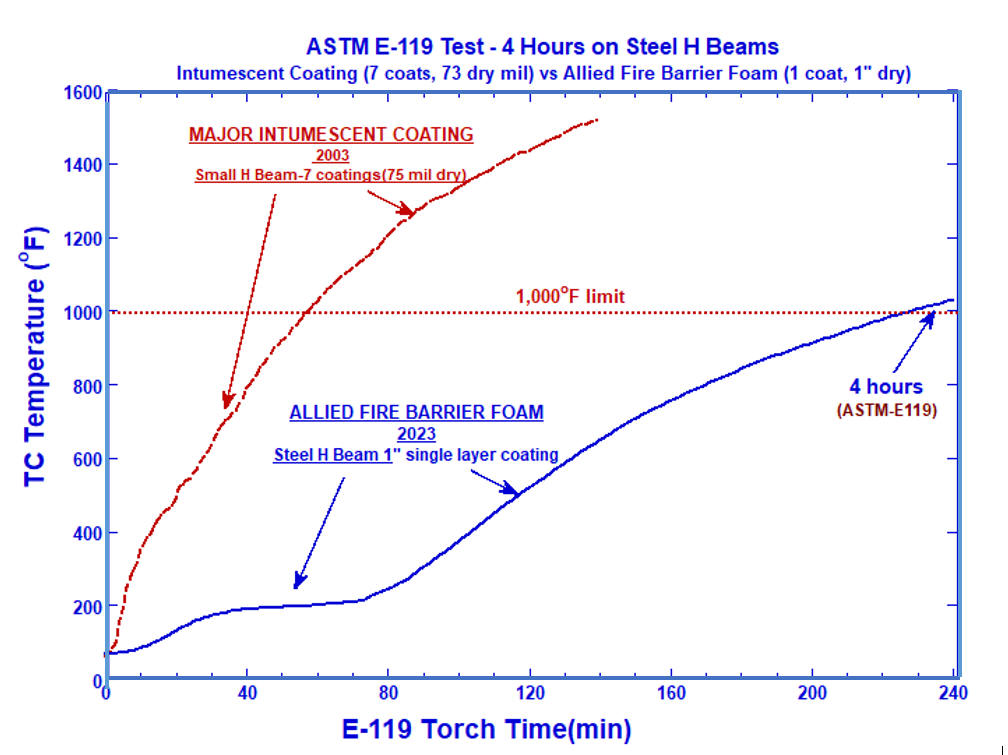

Allied fire barrier foam has twice or better fire ratings per

ASTM-E-119 Test over all fire rated intumescent coatings |

|

| ASTM-E-119 Tested H-Beams with Fire Rated Coatings |

|

|

| H

Beam with Allied Fire Barrier Foam - 4 Hours to 2,000oF |

H Beam with Intumescent Coating

- 2 Hours to 1,850 o F |

|

Allied Fire Rated Foam Slurries Can be Cast as Panels or Sprayed onto Steel Structures |

|

|

|

|

|

`

|

|

|

|

|

Fire rated, easy to handle, allow for pre-cast or cast-in-place manufacture. |

Fire rated, easy to handle, allow for pre-cast or cast-in-place manufacture. |

Sprayable with good adhesion to steel, non-hazardous, no rust & solvent free. |

Sprayable with good adhesion to steel, non-hazardous, no rust & solvent free. |

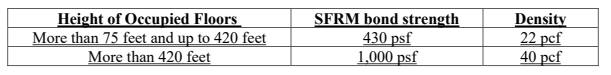

| Excellent Bond Strengh (>> 1,000 psf ) of Allied 35 pcf (565 kg/m3) Fire Barrier Foam to A-36 Steel |

| for > 420 feet (128 meters) Buildings Applications per SFRM (Spray-applied Fire Resistant Material) |

|

| Please click "APPLICATIONS" for detailed ASTM-E119 test results comparing Allied fire barrier composite vs X gypsum & intumescent coatings |

|

OTHER HIGHLIGHTS |

|||||||||||||||||||||

|

HIGHLIGHT - JANUARY, 2016 (World Trade Center Phase II Project, New York) Versatile Compact Foam Cement Mixing Pumping Setup - High Mobility with Good Output |

|||||||||||||||||||||

|

|||||||||||||||||||||

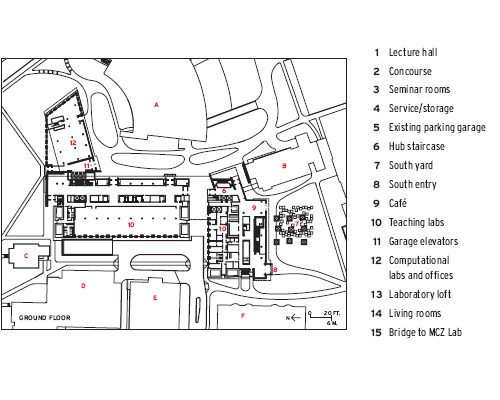

| Landscape Architechture on the Roof - An application with allied low slump foam cement | ||||||||

| Harvard University - NorthWest Science Building, 530,000 ft2 multidisciplinary research facility | ||||||||

| The World's 1st Low Slump Geotechnical Roof Fill used Allied's Cement Composite Design, Foam Products & Machinery. | ||||||||

|

The award winning facility places more than half the total square footage of the facility below grade, and incorporates three functioning green roofs. The south facade of the Northwest Science Building defines a new South Yard, equipped with low landscape furniture. The yard is a green roof over extensive basement levels, with skylights bringing daylight into the underground areas. |

||||||||

|

||||||||

| (Pre-project mockup work by Allied Foam Tech is shown below) |

|

|

|

|

| Mixing & Pumping of High | Applying of High Slump Loss | Finished Foamed Cement Crown | Cross-section of |

| Slump Loss Foam Cement | Foam Cement on 1 Vertical/4 Horizontal Slope | On Highly Sloped Geofoam | Landscape after ~ 1 year |

Foam Cement -

With densities from over 1,450 kg/m3

(90 pcf) to as low as 48 kg/m3 (3 pcf) for

geotechnical engineering

& landscape architecture,

lightweight concrete roof deck,

lightweight wall and floor panels

partitions

lightweight concrete blocks

Pervious Foam Cement - Allied pervious & non-pervious foamed cement are capable for waste encapsulation, immobilization, soil stabilization and leachate filtration. Allied long lasting foam, applied as a surface cover on landfill sites and effluent ponds and lagoons, will effectively suppress noxious odors, vapors, litter and vectors, avoiding serious environmental issues.

Insulative

Fire Bricks,

Panels

-with excellent strength and thermal shock resistance for fabrication of durable firebricks

used as high performance insulative materials for kilns and incinerators.

Geopolymer Foam- Flexible

and very light (< 1.5 pcf or 24 kg/m3). Various geopolymer foam

composites can achieve insulative value R > 3.8 per inch and fire

resistance.

Fire Barrier

Foam -Specially formulated foam from Allied can be used as long

duration fire fighting barriers for the containment of forest fires.